5. Pilot plants for the production of composite plastic materials.

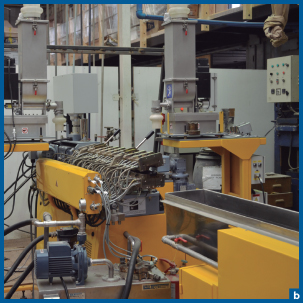

a) Brand and model:Tsa Industriale S.r.l extruder, tsa EMP 45-40.

Capacity:100 kg/hr (thermoplastic compounds).

Description:The plant produces composite materials in the form of pellets or profiles and is composed of three units connected in series: a rotary dryer, a twin-screw extruder, and a pelletizer with pneumatic cooling (manufacturer: Erema).

The rotary dryer is connected to the extruder feed and allows drying of the material before it enters the extrusion stage. The twin-screw extruder has a diameter of 45 mm, an L/D ratio of 40, and is equipped with three gravimetric feeders (Brabender brand); it enables the production of various types of composites (wood-plastic, reinforced plastics, masterbatches, and nanomaterials, among others). It includes various molds.

b) Brand and model:Labtech Engineering Co. LTE26 extruder.

Capacity:30 kg/hr (thermoplastic compounds).

Description:This extruder is capable of producing thermoplastic composite materials in pellet form. It is a co-rotating twin-screw extruder with screw diameters of 26 mm and an L/D ratio of 40. It includes two gravimetric feeders, allowing the production of biodegradable compounds, nanomaterials, and wood-plastic materials.